"It is recalled that in 1896 Henry and Ewald Schniewind, German textile manufacturers were known to be interested in establishing an industry in the United States and word of that fact came to Frank R. Slifer, at the time Reading Railroad agent in Sunbury

He advised Harry S. Knight, local attorney, now deceased, of the plans and they greeted the Schniewinds when they landed New York City, brought them to Sunbury and showed them potential industrial sites.

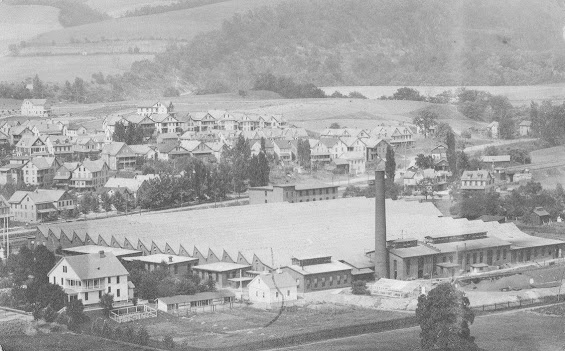

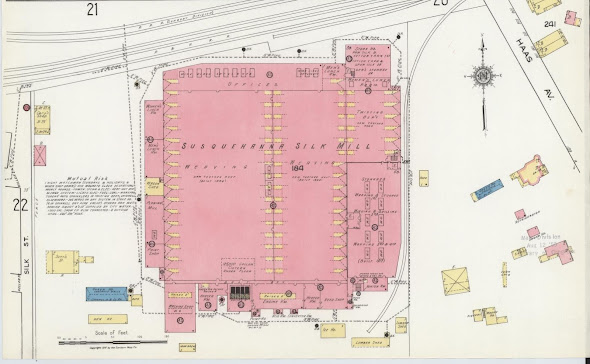

The Hiram Haas farm. on which a large fairground was located became their choice and was purchased by popular subscription and turned over to the Schniewinds who built there a silk mill that was to develop into a chain of 11 plants along with the Sunbury Converting Works, a dyeing and printing facility located in the building occupied by the Celotex Corporation.

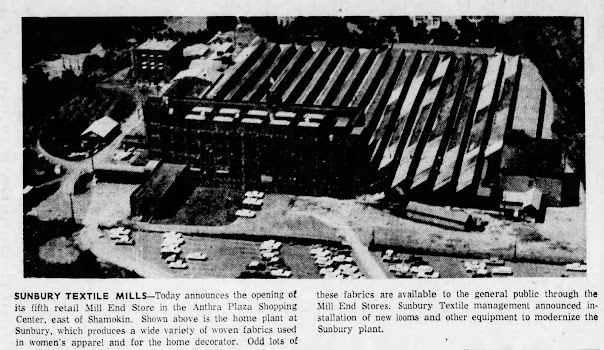

When hard days came upon the textile industry. the local silk plant was the last of the Susquehanna chain to be phased out. In addition to the Sunbury plant Sunbury Textiles has four mill outlets--two in Sunbury and one each in Williamsport Port Trevorton. Sales by the New York City sales office of the firm cover all areas of the United States and Canada."

About Converting Silk

Converting silk required several steps. First, 100-yard pieces ran through a singeing machine to burn away slubs or flaws. Then the pieces were soaked in boiling suds and bleached to allow the dyes to absorb evenly into the fabric. Workers moved the fabric to the dye house, tinted it in large vats and dried it on large steam-filled drums.

After it was completely dry, the fabric was lightly starched and finished.

1896 Ground Breaking

1903 - The company added the converting works to it's operation in 1903.

The first product made at Sunbury Converting Works in the northern end of the city was a 500-yard piece of 18-inch wide satin dyed Nile green by dye master Adolph Selter.

After the silk industry collapsed and synthetic fabrics flooded the market, the factory was home to Westinghouse Electric Corp., which had government contracts to produce goods during World War II. Westinghouse left Sunbury and moved its operations to New Jersey in the early 1950s. Later, new owners converted the sizable plant to manufacture pulp and fiberboard building products made over the years by Barrett, Jim Walter and Knight-Celotex corporations

1954, May 17th - Susquehanna Textile Mills at Sunbury reopened as Sunbury Textile Mills Inc. "In 1954, Sunbury Textile Mills opened its doors, set up its looms and began weaving decorative jacquards in Sunbury, Pennsylvania. Fifty years later, we've become one of the most influential mills in the world, bringing innovation, performance, and unprecedented quality to our age-old industry."

1956, March 20 - Protection Fire Equipment, which occupied the third floor of the five floor section of Sunbury Textile Mills, was surveying the possibility of using two additional floors, and possibly eventually using all five floors. Each flood had 20,000 feet of manufacturing space. The company manufactured polvonite protection football equipment, ensolite mats and floor and wall padding, and was "one of the areas newer industries"

1958, Dec - sites for four 200-bed hospital units for use by the county CD [Civil Defense?] Council were approved . Two units were to be stored n the first floor of the Sunbury Textile Mill, one in the former Dalmatia High School, and one at Shamokin State Hospital.

1963 - First Lady Jacqueline Kennedy chose a Lokpuf damask manufactured by Sunbury Textile Mills, to cover a buffalo horn chair she had found at an antique store, for the White House.

The Knight-Celotex building closed in 2008, and was demolished in 2011.

READ MORE

===============

Sunbury Textile Mills was founded in 1954. It was purchased from the Susquehanna Silk Mills, a silk tie manufacturer which built the original manufacturing complex in 1890. A more modern facility was erected in 1970, housing today’s modern looms and manufacturing equipment while also keeping the original saw-tooth roof, an architectural signature from the turn of the century. Our sales and creative design offices are located in a historic, cast iron building dating back to 1861 in the vibrant neighborhood of SoHo in New York City.

Sunbury has always operated at the present manufacturing site in Sunbury, Pennsylvania and is one of the only mills of its type that continues to manufacture 100% of its products in the United States of America. In 2004 Sunbury Textile Mills became an ESOP (Employee Stock Ownership Plan) company and is owned 100% for the benefit of all the employees’ retirements. We employ multigenerational families that carry on the art of weaving with an average tenure of 20 years of design and weaving expertise.

We are extremely proud of our reputation for excellence in product quality, superior design and unsurpassed levels of customer service. We are a market leader in the design and manufacture of decorative jacquard fabrics for the world market.

No comments:

Post a Comment

I'll read the comments and approve them to post as soon as I can! Thanks for stopping by!