|

| Lower Market Street, Milton PA |

The Milton Manufacturing Company of Milton Pa was organized in 1886 and incorporated in 1893.

1906 Fire

===========

|

| The Shell Plant in 1919 |

"In 1915 the company built an additional plant for the manufacturing of gun shells. Soon thereafter they entered into a contract with the British government to manufacture 200,000 6 inch high explosive shells."

3'rd Turn Foremen, M.M. Jan 1919

Stahley, Mowers, Hawley, Rean, Boughter, Liddick, Huffman, Coates, Balshi, Ulrich, Wiekel, Schwab, Weber,

Echelberger, Spache, Mitzel, Larrimer Spt, Redding Gen. Foreman, Frush, Asst. Gen Foreman, Farmer, Koons

"Resolved, that permission be granted the Milton Manufacturing Company to erect and maintain a twelvewire line on the north side of railroad siding, crossing on South Front street, and across Cameron avenue, for the purpose of conveying electric current from their power plant to the several buildings of the Milton Manufacturing Company; said construction to be under the supervision of the street committee." January 1919

"Since its organization, the company has been engaged in the manufacture of refined bar iron, hot pressed and cold punched nuts... " The Miltonian, 1919

In 1965, it became a division of Ceco. In 1972, the company suffered five million dollars in damage and loss.

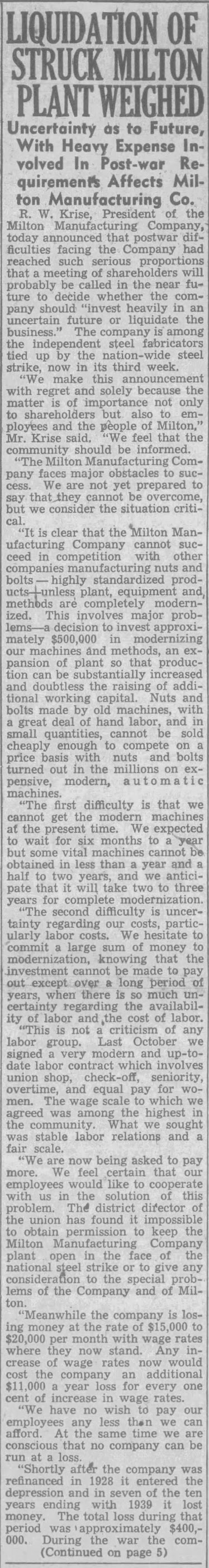

In 1946, They Were Facing Liquidation

==========

In 1985, New Company Formed

=============

In 1985 Milton Manufacturing partnered with a Canadian Corporation to build a 7,500 sq foot building on Shakespeare ave and Mahoning street, to employ 6 people. The new company would coat steel reinforcing rods with rust proofing epoxy.

"The Milton Manufacturing Company, identical with S. J. Shimer & Sons in ownership and management, was incorporated several years since and buildings were erected between the Philadelphia & Erie and Philadelphia & Reading railroads for the purpose of developing such specialties in the iron trade as should be found advisable.

The original idea was never successfully carried out, however, and it was not until the fall of 1888 that the works were placed in operation under the present management. The plant consists of two frame buildings; the smaller is forty-five by one hundred twenty-five feet, with engine room attached, and in this building are four double puddling furnaces and one train of muck iron rolls; the larger building, sixty by two hundred seventy-five feet, contains one heating furnace and a ten-inch train of rolls, with other appliances for a complete rolling mill plant, and washer-cutting machines (originated and patented by Mr. Shimer in 1889) which cut from four to six standard washers at each stroke

. The daily capacity is eight tons of plate iron and from ten to twelve thousand pounds of finished washers. The number of operatives varies from seventy-five to one hundred." - The History Of Northumberland County By Bell

===========

The Milton Manufacturing Company of Milton Pa was organized in 1886 and incorporated in 1893.

"Since its organization, the company has been engaged in the manufacture of refined bar iron, hot pressed and cold punched nuts... " The Miltonian, 1919

More About The Shell Manufacturing Plant

===========

"In 1915 the company built an additional plans for the manufacturing of gun shells. Soon thereafter they entered into a contract with the British government to manufacture 200,000 6 inch high explosive shells. That plant went into operation in March of 1916, and continued for roughly one year.

The steel for making these shells was purchased by the company from the Republic Iron and Steel Company, Youngstown, Ohio, in billets and was rolled in the company's plant into rounds, which were at first sawed, and afterwards scored and broken into blanks, from which forgings were made and from such forgings the shells were machined.

"After the termination of the British contract, the company entered into a contract for the rolling of steel furnished by the Pollack Steel Company for Gio, Anslado & Company, who were engaged in the manufacture of shells in Italy for the Italian government. This operation began April 30, 1917, and continued until July 20, 1918 during which period 47,628 tons of steel were rolled.

As the company had no use for its shell-making machinery in its regular business, such machinery was being offered for sale, after the termination of the British contract, when the United States declared war on Germany. -The officers of the company promptly responded to a request to attend a council of defense at Washington, where they accepted a contract from the United States Government for forging and machining 200,-000 4.7 inch H. E. gun shells, with the understanding that operation was to start promptly, and the contract was to be fulfilled by September 1, 1918. Soon thereafter the need for 4.7 inch gas shells arose, and the company was asked to take a further contract for the manufacture of 200,000 gas shells to be delivered by September 1, 1918.

The shell-making plant of the company had been equipped especially for the manufacture of 6-inch shells, and when the change was made to 4.7 inch shells, the company's machinery capacity was materially increased without an increase in its forging capacity .which necessitated the installation of additional forging facilities in order to meet the requirements of-; its two- contracts. The United States agreed -to furnish all material to be used in the manufacture of such shells, and the quality of steel to be furnished did not require heat-treating.

Before deliveries began the Government made a change to the quality of steel which was furnished, as a result of which, all shells manufactured were required to be heat treated, in order to meet the necessary physical tests. Water quenching was permitted to such heat treating; and the company arranged for the installation of water quenching heat treating facilities. This was soon afterwards changed to oil quenching. The company then installed new equipment for oil quenching heat treating of all shells.

The company naturally experienced difficulties usually incident to the starting of work of this kind, all of which were rapidly overcome and production soon began to increase. Government representatives were stationed in the plant of the company for the purpose of making a study of the best method of increasing production, and the recommendation's of such officers required the installation of large quantities of additional machinery in order to double the shell-making capacity, which was the Government's aim.

The Milton Manufacturing Co., spared no expense in the purchase and installation of needed additional facilities. It soon developed that the supply of electric power used in operating the plant was not sufficient for the needs of the company, and the lack of such power proved to be a serious handicap during all of the time that shells were being made.

As a result of the allocating of some -of their electric current, it became necessary for the 'company to construct an electric generating plant with a capacity of 4000 K. W., which plant had not been completed when operations under its contracts were suspended (but which has since been completed).

The Milton Manufacturing Company had in its shell manufacturing plant alone, motors necessary for the operation of its machinery and equipment of a rated horse power of 5400. The company was required to convert into H. E. shells a large number of gas shells in process of manufacture.

A The company completed its first contract for H. E. shells, almost within the contract period, and this in the face of many difficulties which were caused by the general excitement in ident to hurry 6en a country is at war.' " Meanwhile the company had received a further contract for the manufacture of 700,000 4.7 inch shells, of which 800,000 were to be gas shells and 500,000 were' to be H. E. shells. This contract was to have been completed by June 30, 1919. Deliveries of H. E. shells under this contract began in September, 1918, and continued until the suspension of contracts, including the manufacture of gas shells, of which about 50,000 additional were delivered before suspension.

During the month of December 1918, the Government requested the company to suspend operations under its contracts, which request the company accepted and the operations ceased on January 81, 1919, the company having manufactured in all 574,564 4.7 inch gas and H. E. shells out of the total 1,100,000 shells which it had contracted to manufacture.. In addition the company manufactured about 40,000 shell forgings for the United States Government, which were shipped to other contractors to be machined.

The company had retained the frame work of its organization, which had been built up for its British contract. To this a large number of workmen were added. As its operators were taken from it for service in the army and navy, the company found it necessary to employ women operators, in anticipation of which, by the request of the government, rest rooms and other suitable conveniences were installed by the company for the convenience of female labor.

In all, the company employed over 2200 men and women in its shell making plant, of whom seventy were females. The number of female operators would have been largely increased had the war continued. The company also employed about 800 men and women in the manufacture of iron and nuts in its original plant. The Government supplied a force of forty-one inspectors, under whose supervision and inspection, all shells manufactured by the Milton Manufacturing Company were made and delivered.

It is a well-known fact that the 4.7 inch gun was one of the very few types of gun which the United Slates Government was able to manufacture and use in the equipment of a complete battery for service in France, and for that reason the manufacture of this type of shell was of vital importance to the Government. The Milton Manufacturing Company, has a record of having made more 4.7 inch gun .shells than any other contractor.

As the result of accurate engineering and skillful practice, the Milton Manufacturing Company was able to show many importance economies in the pursuit of their Government work, and their products were always of the very highest standard of manufacture." - The Miltonian, 1919

You forgot to mention that the mill was purchased by Fred Cormell in 1982 from the Ceco Corporation.

ReplyDeleteI was chief chemist for Ceco and helped new set up at Milton. Nice little towwwn.

ReplyDelete